Blog

All

All

Bible Repair

Bindings

Book Arts

Bookbinding

Conservation

Endpaper Challenge

Hong Kong

Papercuttings

Printmaking

Repair

Restoration

Workshops

From

To

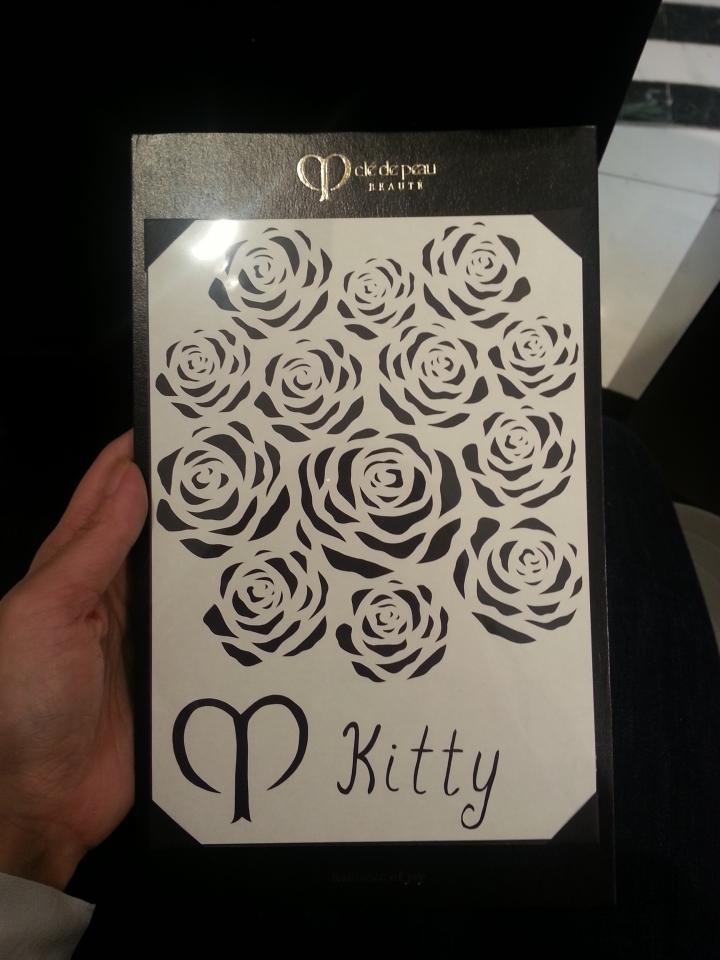

Customised Paper Cutting for Events

2022-04-12

Prior to the pandemic, companies would hold VIP events. The pandemic has caused a lot of these events to be cancelled or postponed indefinitely. Companies would contact me about doing paper cutting events, normally they request silhouettes of the customers, but then I suggest a paper cutting that is more suitable to promoting their brand. Like the paper cutting above which I designed and cut for a Cle de Peau VIP event, I would discuss with the company to understand their brand and what they value and design a paper cutting that suits their brand identity. I pre-cut most of the design ahead of time so that I have enough time during the event to customise each paper cutting for the VIP customers. Most people don’t know that it takes a few minutes to just cut out the name. I have around 5 minutes per cutting with a bit of time in between each cutting for a buffer, and for a full day event I aim to do around 80 cuttings.

Read More

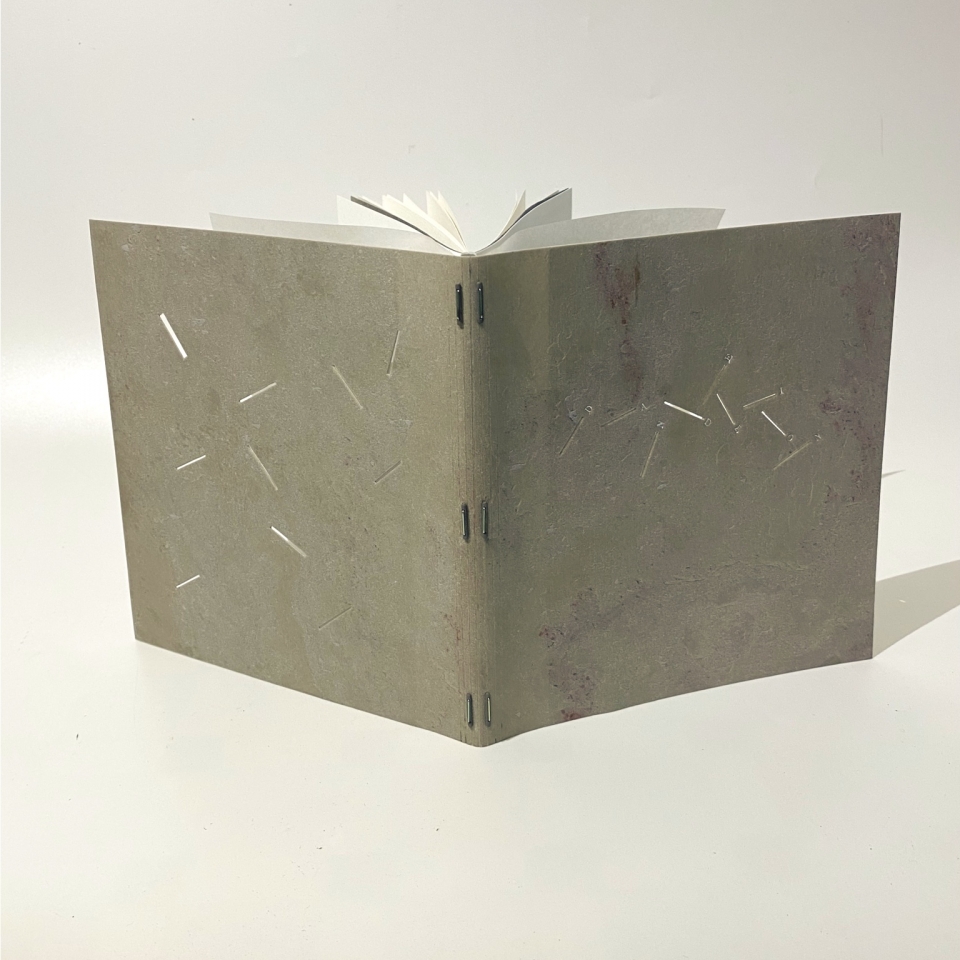

Dandelions

2022-01-10

Happy new year everyone! To start off the year of 2022, I would like to show you one of the bindings that I did last year. This book is called Dandelions, it’s a poem written by my client David Rowland. I decided to use Sün Evrard‘s stone veneer staple binding structure because of the size of the book. Each page has one line of text and an illustration that I drew. Both the front and back cover have incisions representing dandelions floating in the air. The title is tooled onto the front in silver.

Read More

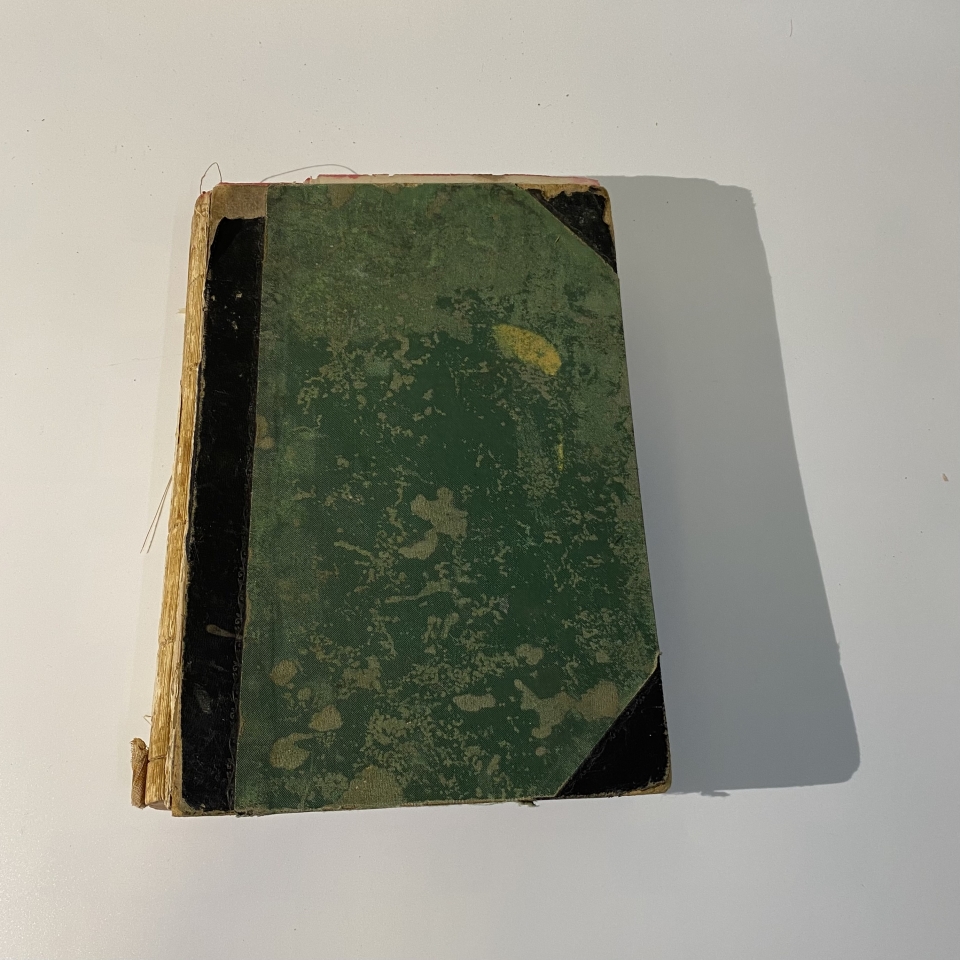

Rebacking of English and Chinese Dictionary

2021-12-14

This is the other leather reback that I did recently. The book is half bound in black leather, with the rest of it in green book cloth. From the photos you can see that the leather spine has torn off and the first few pages are detached from the text block. This is an English and Chinese dictionary written by Kwong Ki Chiu, the first Chinese person to write and English dictionary.

Read More

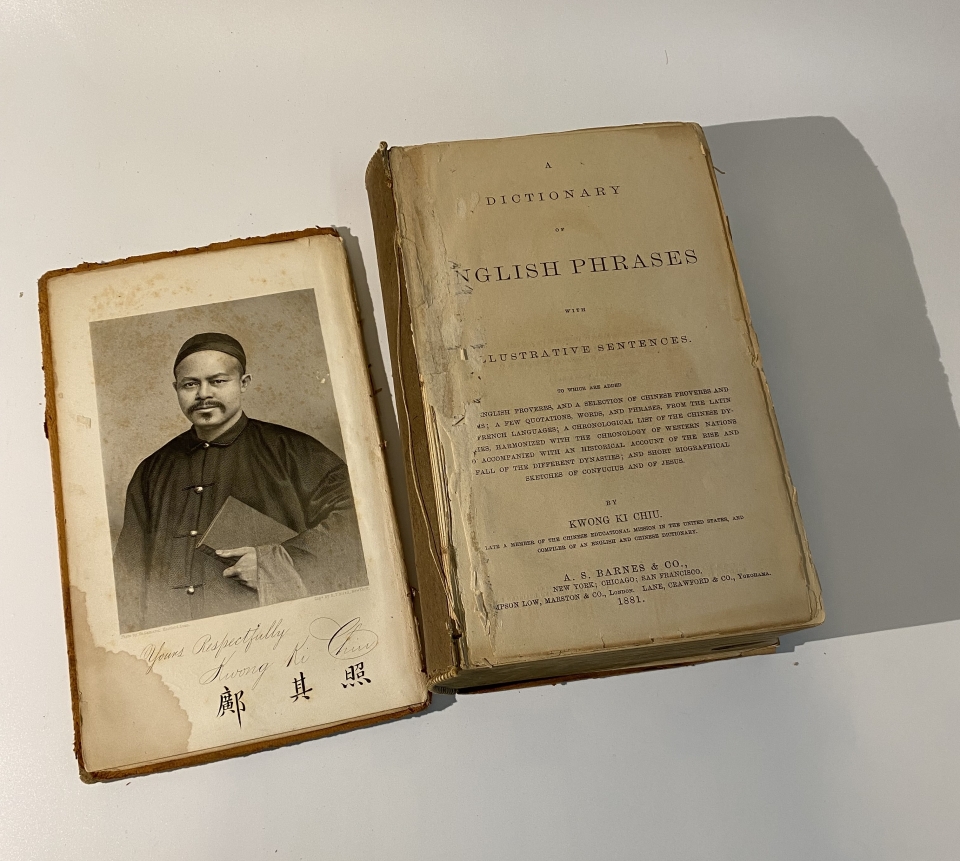

Rebacking of English Dictionary of Phrases

2021-12-13

I just realized that I haven’t posted a blog in nearly a year! This year has been tough, I suppose it has been for most people because of the pandemic. I haven’t been able to work for an extended period of time because of an accident causing me to be unable to move around freely. That being said I have been able to work on some interesting projects over the last few months. There’s been a flow of repair work from clients, the latest ones have all been rebackings, two leather and one cloth.

Read More

Rebindings

2021-01-08

We all look forward to a brand new year hoping for brand new things. 2020 was challenging for everyone no matter what due to the pandemic and also other issues. A large part of work has been put on hold and postponed, my classes with students have been disrupted. Not having the physicality of meeting and sharing has taken a toll as my work is solitary. With people working from home they have gone to their bookshelves for comfort and many who are religious have looked at their bibles and wanted to rebind their precious possessions.

Read More

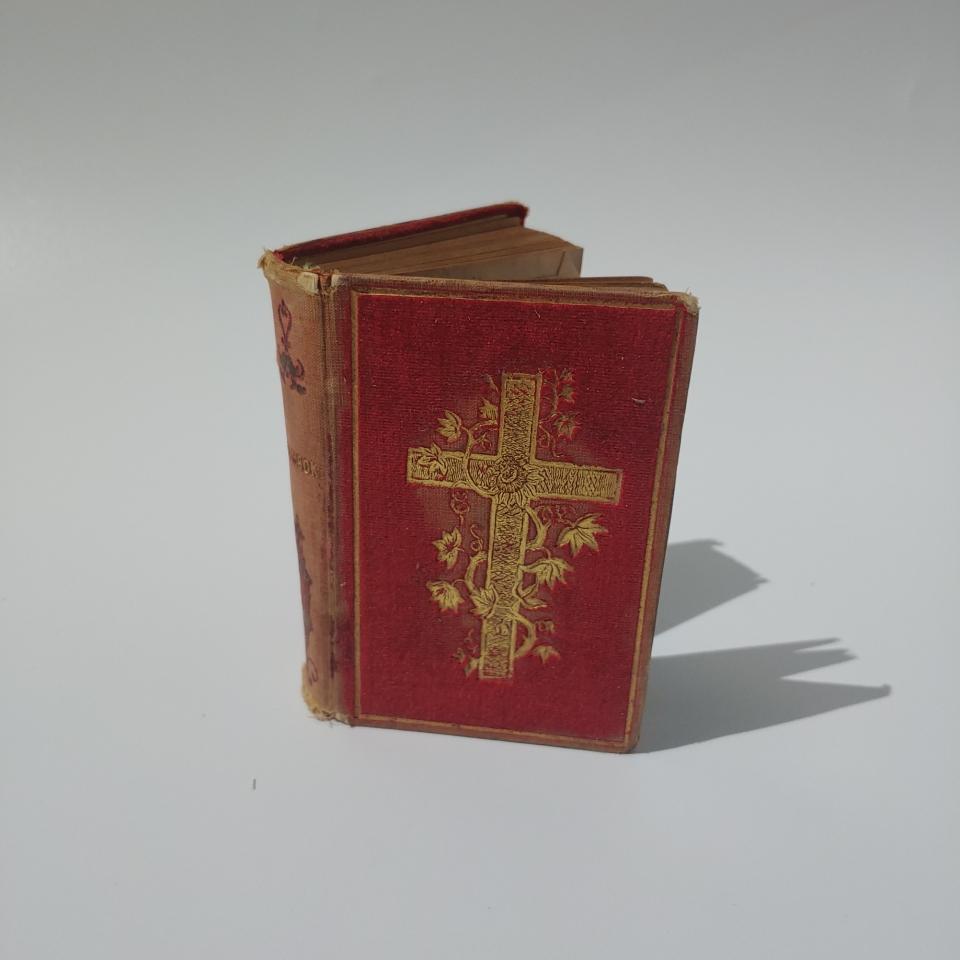

Book of Psalm

2020-08-29

This is a Swedish book of Psalms bound in velvet with gold tooling on the covers and spine, all three edges are gilt with minor gauffering. The gauffering is not very visible, as a small tool was employed and tooled close to the spine of the book. I've asked a few friends about the minimal gauffering and if there's a specific name for it or a reason why it only has minor gauffering, so far no one has an answer yet. Please email me if you have come across anything like this and can shed some light about this issue!

Read More

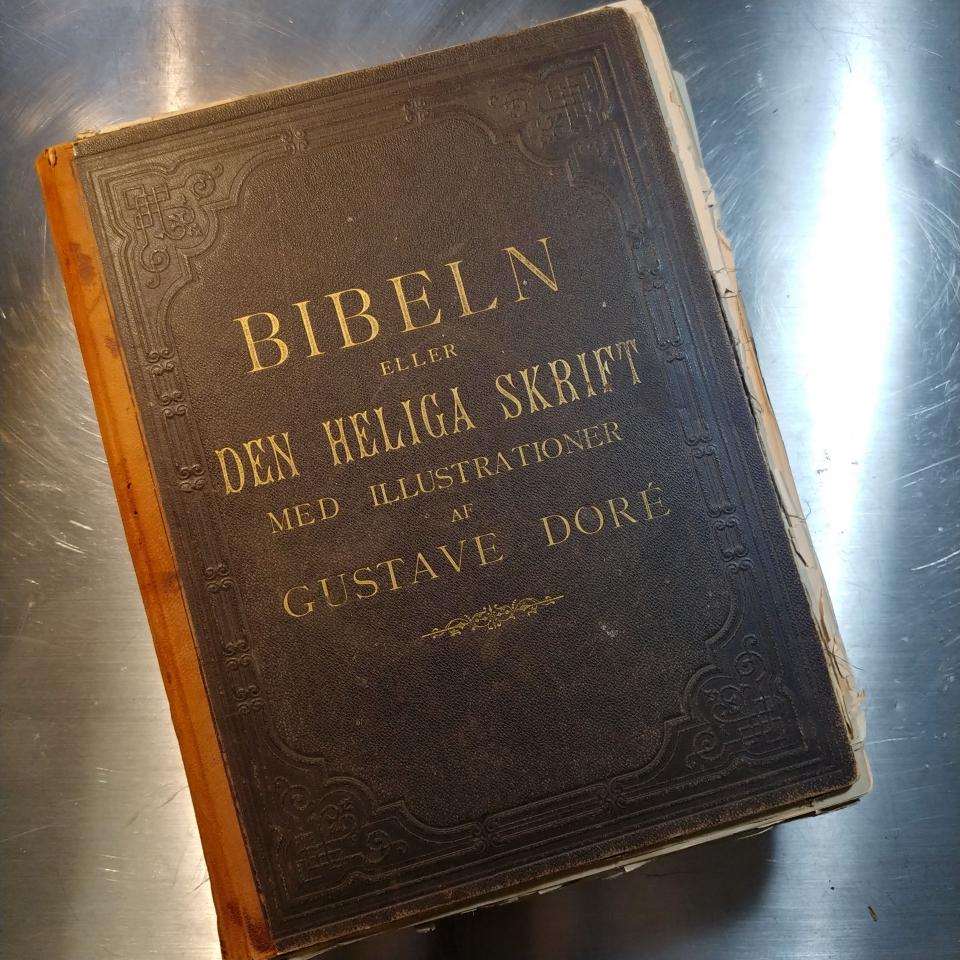

Bible Repair 1885

2020-05-30

My client came to me with a Swedish family bible from 1885. This is the largest bible that I have repaired to date! My friend Jonathan did a video walk through of the bible for his bible study group.

Read More

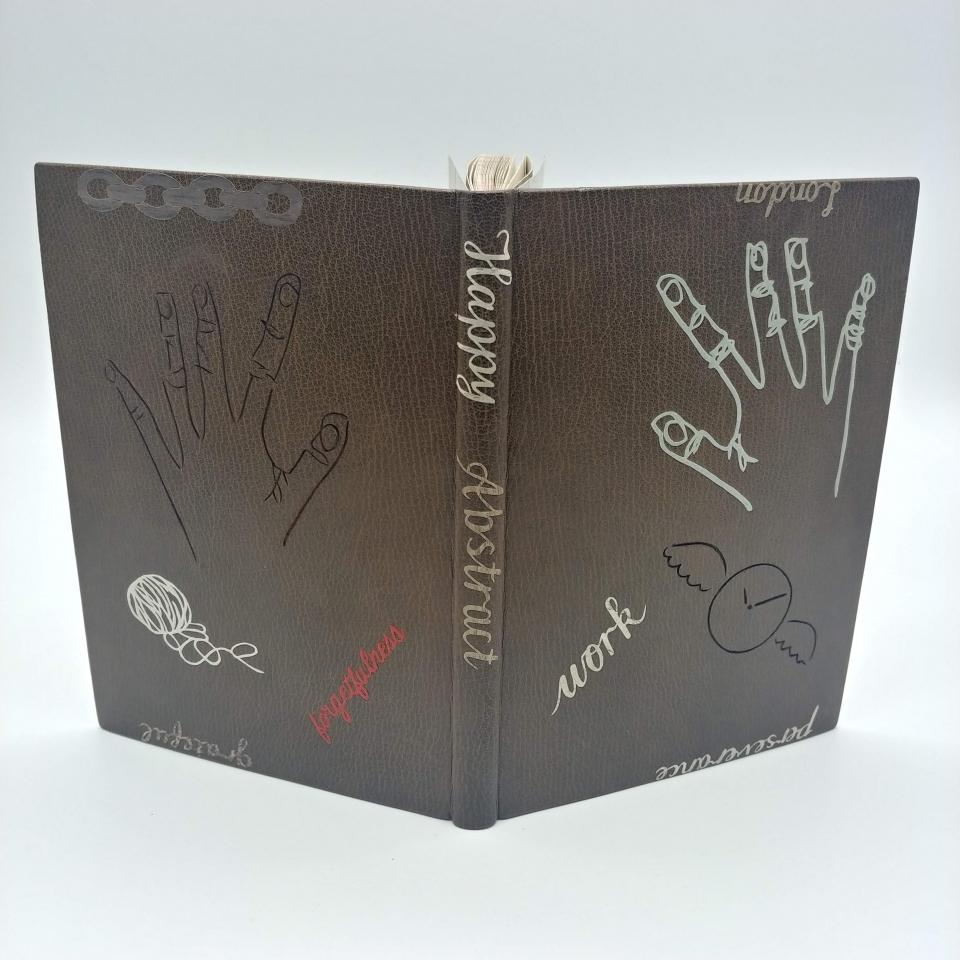

Open•Set Competition 2020 by American Academy of Bookbinding

2019-11-18

I'm happy to announce that my set book for the Open•Set Competition 2020 has been chosen among 100 other bindings to travel in the US next year. Happy Abstract- A Letter by William Blake is the set textblock for this competition. The book was quite difficult to work on due to the nature of the text. The letter is a poem that William Blake wrote to his client Thomas Butts about how he is unable to finish the work in time.

Read More

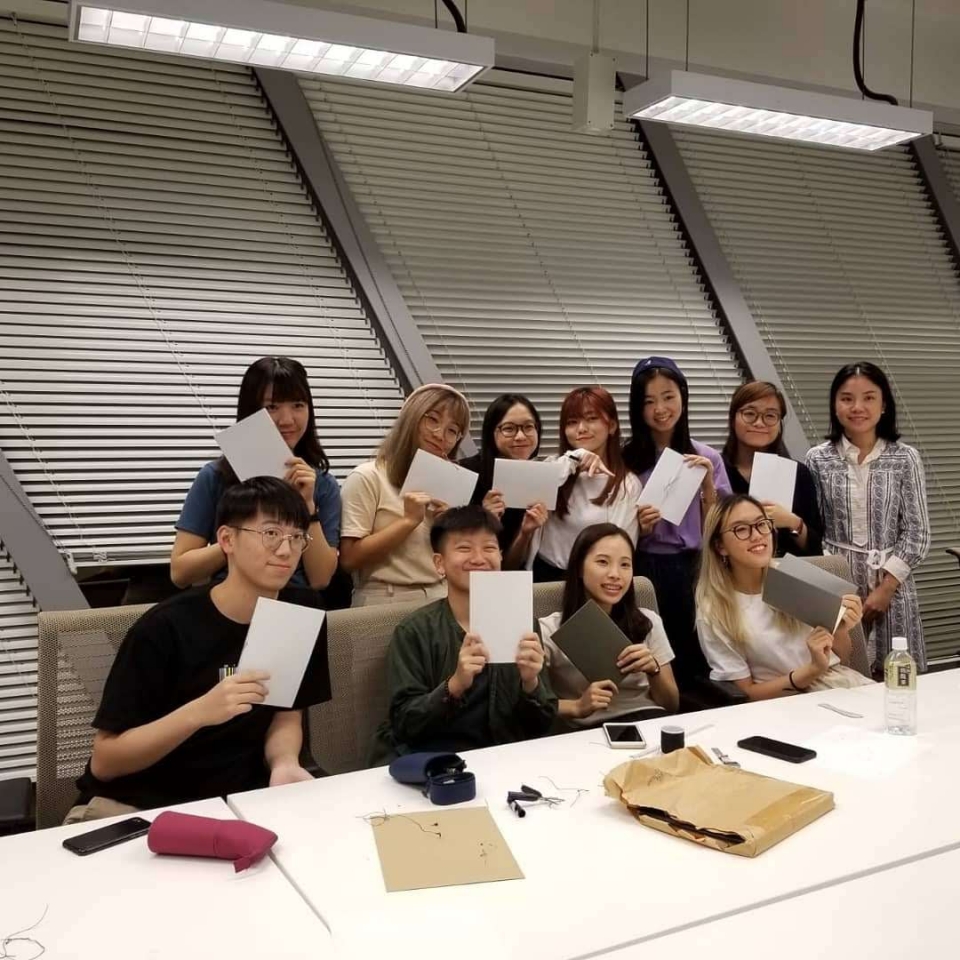

Polytechnic University School of Design Workshop

2019-10-15

Last month I conducted a bookbinding workshop at The Hong Kong Polytechnic University. The students attending the class were from the School of Design. The class was over subscribed, there were supposed to be 15 students but some students on the waitlist ended up coming to the class. We managed to accommodate for more students by cutting more materials last minute.

Read More

Hong Kong Archives Society Workshop

2019-02-11

I was invited by the Hong Kong Archives Society to conduct a workshop at the Living Medical Heritage in the Community Carnival. We chose to do a four flap enclosure as a protection for books, documents and objects. This workshop was catered toward a preservation crowd so I took a different approach to teaching than my other workshops.

Read More

Bible Repair & 4 Flap Enclosure

2019-02-11

I can't believe how fast time has gone by. It's already mid February! I haven't been able to post on my blog for the last few months as I was experiencing some technical difficulties, that has now been solved and hopefully won't be an issue anymore. I started a new instagram account dedicated to my books and paper art, the instagram link has been changed to that and the handle is @percybookbinder. Please follow me if you haven't yet.

Read More

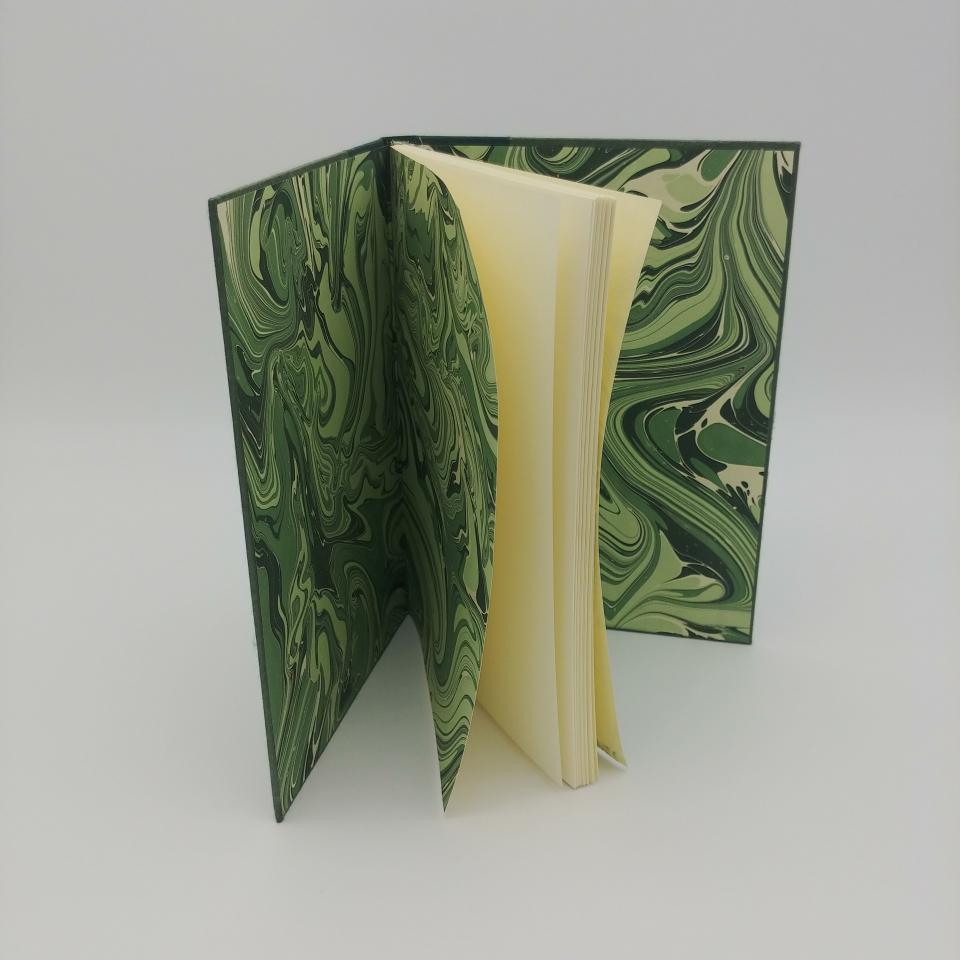

Endpaper Challenge #3

2018-10-27

Endpaper challenge #3 is a simple tipped on endpaper. Arthur Johnson describes it as “the cheapest and weakest, 3, is not sewn but tipped on the section for 3mm. All publishers’ edition bindings have this endpaper.” The photo above shows the textblock sewn with the endpapers ready to be tipped onto the first and last signature/section. The endpapers are Cockrell marbled papers that Flora sent me with some other marbled papers that I will use for the other endpaper challenge books.

Read More

Endpaper Challenge #2

2018-10-26

Arthur Johnson describes method 2 as "not elegant but it is reasonably strong as it is sewn in with the section and reinforced with mull.” This second method is a single signature textblock with the endpaper and cloth reinforcement sewn on. It's a quick and simple way to make a small thin book.

Read More

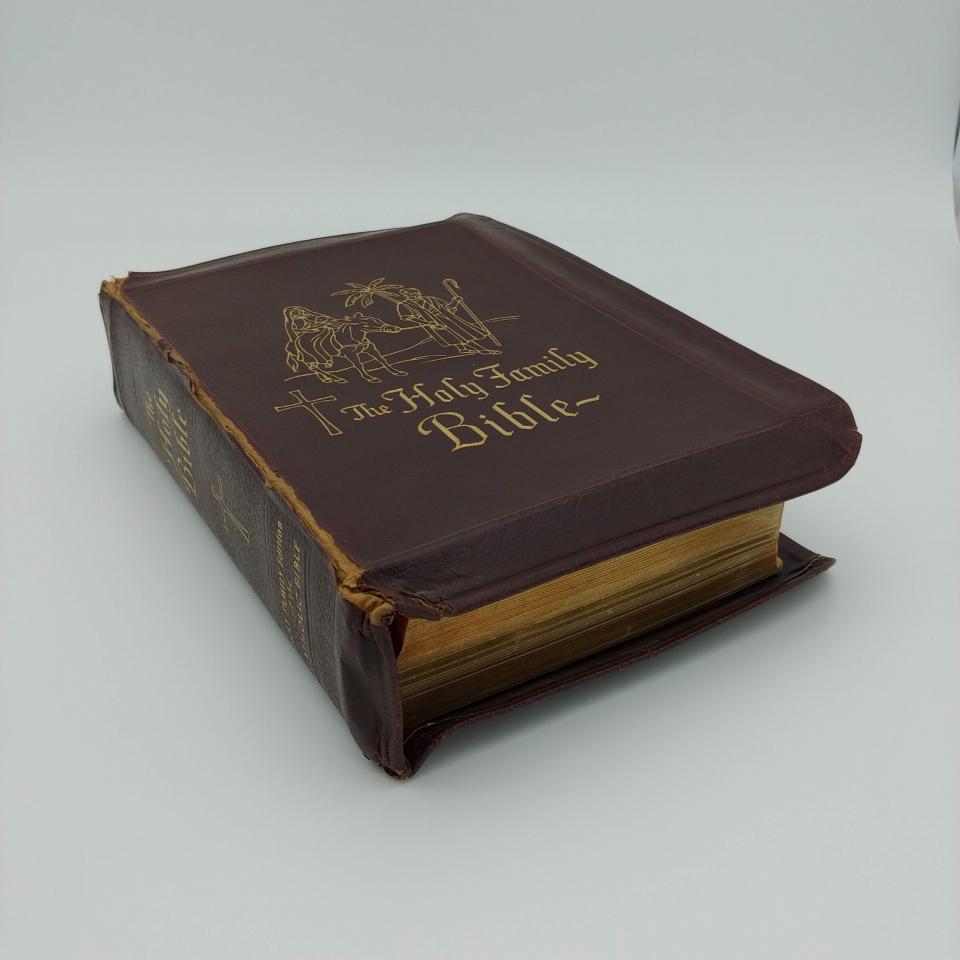

Family Bible Repair

2018-10-12

I have been getting a few bible repair jobs lately which has been quite exciting! I love seeing bibles from different time periods. I have talked to a few different people about repairing bibles, it is difficult work largely because the value of the bible is more sentimental than the monetary value so it's very hard to give a quotation for the work that is considered reasonable for the client. I have been lucky to get bibles that people do treasure and I am given enough time and resources to work on them. This bible was in pretty good condition other than the hinge on the front cover and the corners of the yapp.

Read More

Endpaper Challenge Week 1

2018-09-25

When I was in London in the summer, Flora Ginn was telling me about making endpapers. I had no idea about what she was talking about! I thought that if you say you are making your endpapers that means that you are making the decoration for the paper such as marbling or paste paper.

Read More

Lingnan University Orientation Bookbinding Workshop

2018-09-11

I was invited by Lingnan University to instruct a bookbinding workshop during orientation week. Lingnan University is a liberal arts university in Hong Kong, they are affiliated with my alma mater Carleton College. I have previously taught at Hong Kong University and also at PolyU HKCC, even though with teaching experience at other tertiary institutions, this workshop was a bit challenging due to the large class size and the time limitation.

Read More

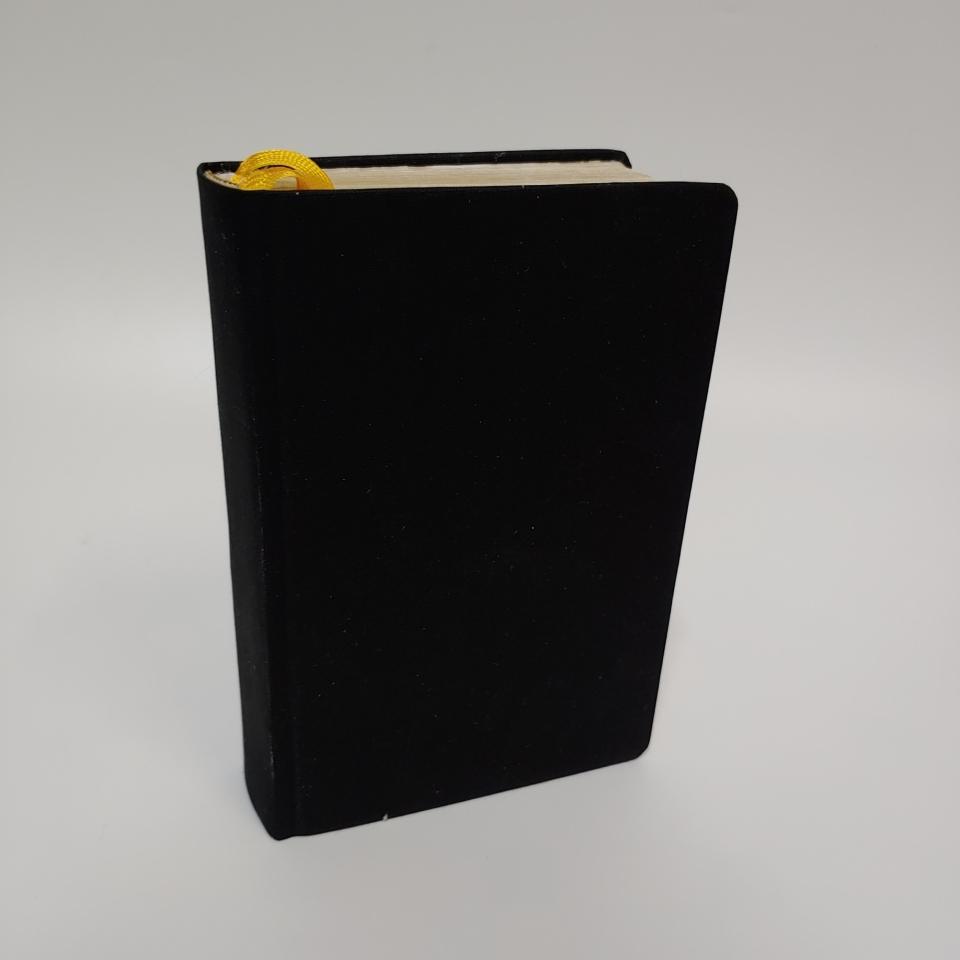

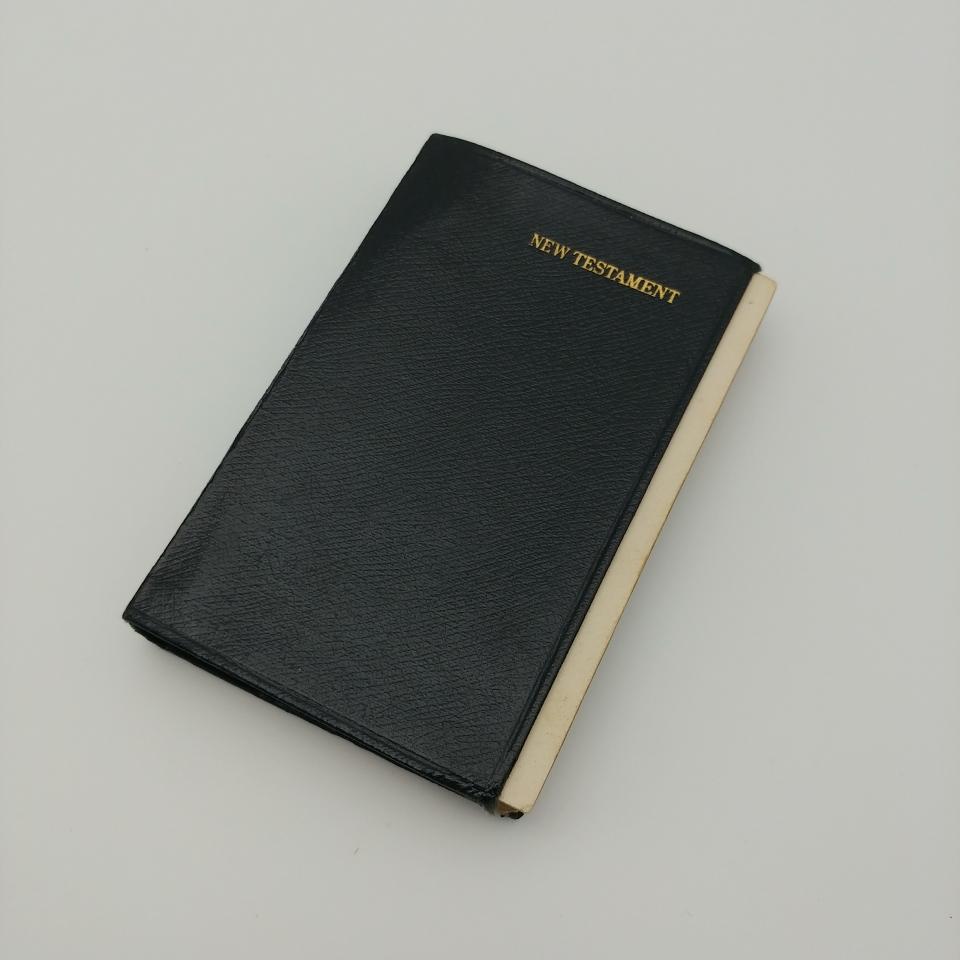

Bible Repair

2018-08-24

I just returned a bible that I repaired to the client. This client is a childhood friend of mine, we went to church together and grew up together. His dad recently got ordained to be a pastor, so as his gift to his dad's accomplishment he asked me to repair this bible. When I got the bible it was in a bad condition, the cover was held together by tape and so were most of the pages of the textblock.

Read More

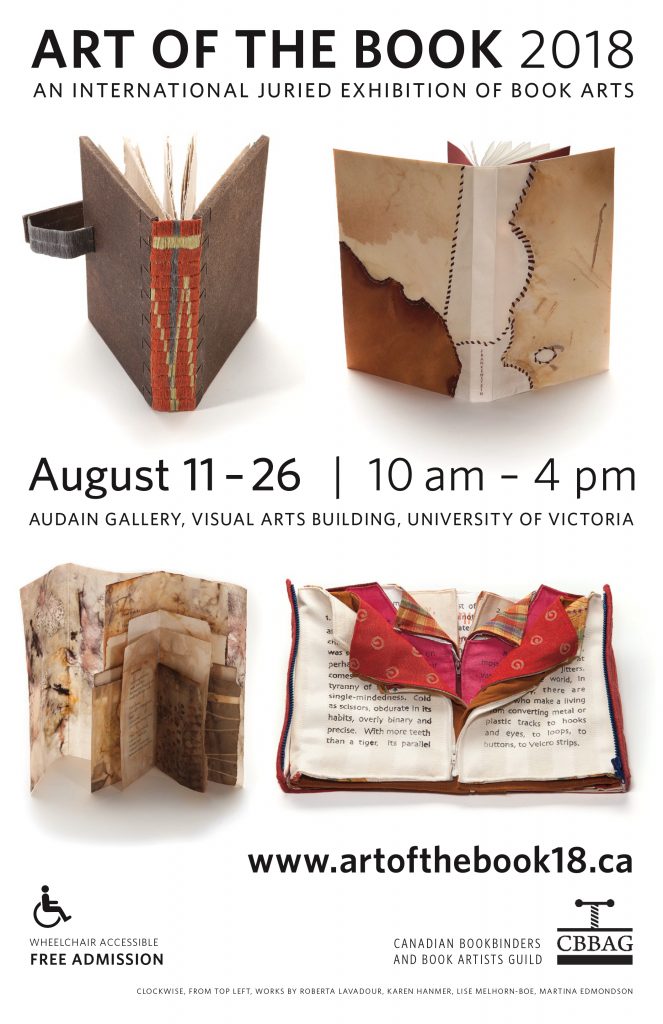

Art of the Book 2018

2018-08-08

I entered "the Staircase" an artist book into Art of the Book 2018 and it will be travelling to different exhibitions across Canada for two years. Art of the Book is a juried exhibition of the Canadian Bookbinders and Book Artists Guild members' work. The exhibition includes many different categories, calligraphy work, artists books and also fine bindings. In total sixty-seven works from eight different countries were chosen to be a part of the travelling exhibition.

Read More

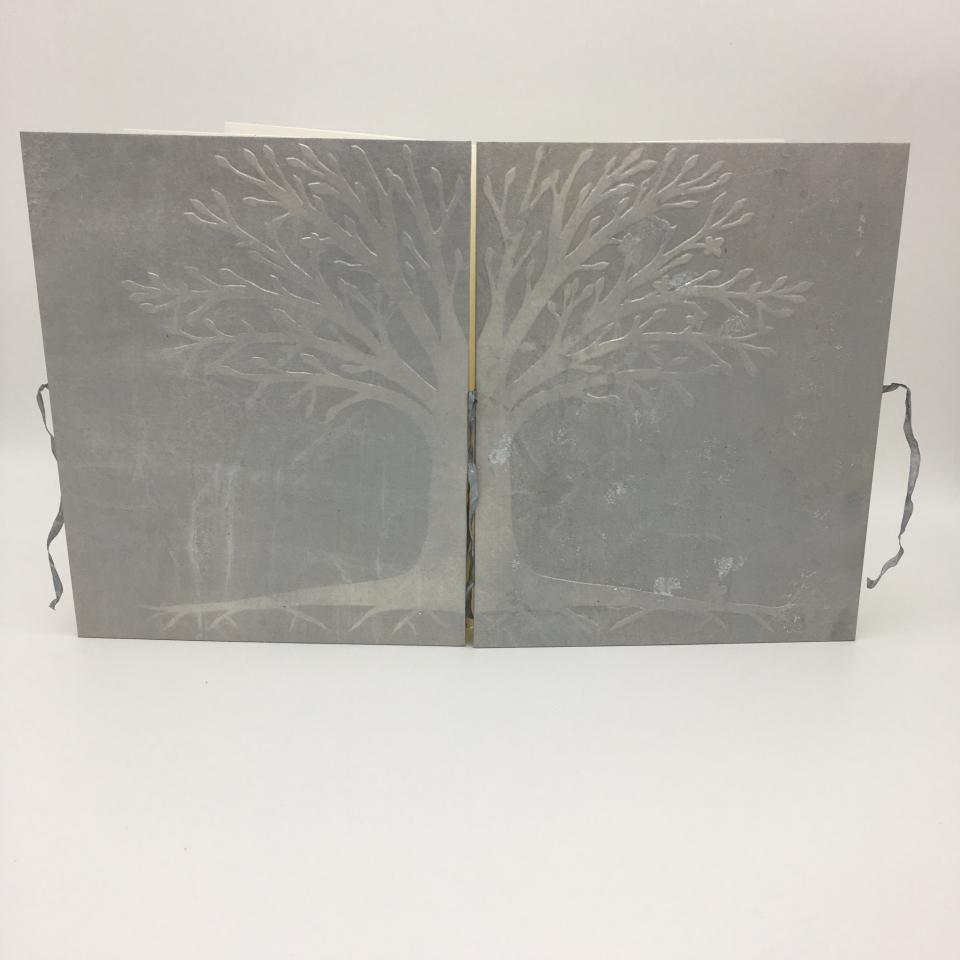

Family Tree

2018-07-30

This is a guest book that I made for a client for her husband's parents' 60th anniversary party. Sometimes working with clients they have a very clear idea of what they want. It's hard to gauge initially if they want your creative input, or if they just want someone to execute their idea. With this client, she came across my website and wanted to commission a guestbook. As with all commissions I ask the clients about what they are looking for and give suggestions based on their requirements. She had an idea of how many pages this guestbook should be based on how many people would attend the celebrations.

Read More

Staple Stone Veneer Binding

2018-07-24

On the Europe bookbinding trip that I took with American Academy of Bookbinding in 2011, we got to meet Sün Evrard, a Hungarian bookbinder who is based in France. We were lucky to be able to see her staple binding made with different materials. I was particularly drawn to the stone veneer, as with most people. Since then I have always wanted to learn how to use stone veneer in Sün's way. Coleen Curry learnt how to do this binding at Sün's class a few years ago and has been teaching other students this binding structure.

Read More

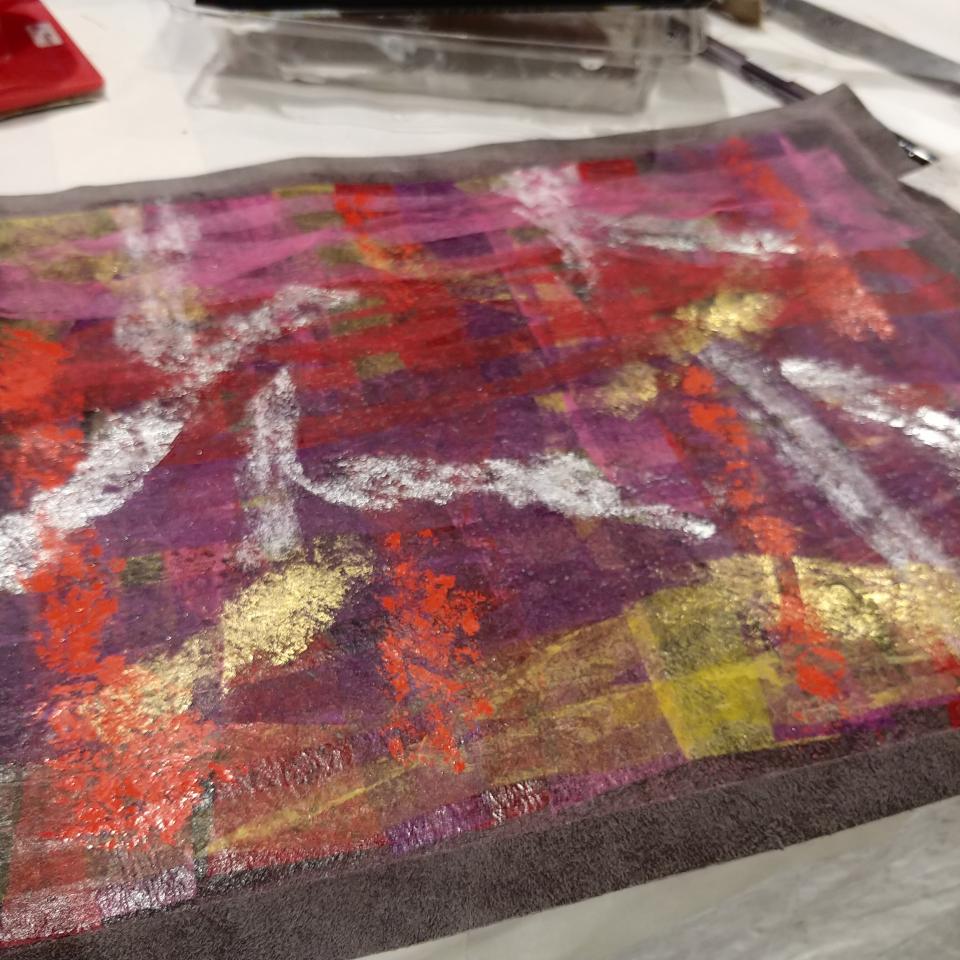

Leather Manipulation

2018-07-16

Sorry I haven't posted for a while. I had some issues in June with my server and lost a lot of blog posts, all of them has somehow drifted into the internet abyss. In the past few months a lot has changed and I have lots to write about but never enough time and I get distracted easily. I nearly got distracted and forgot that I was writing this!

Read More

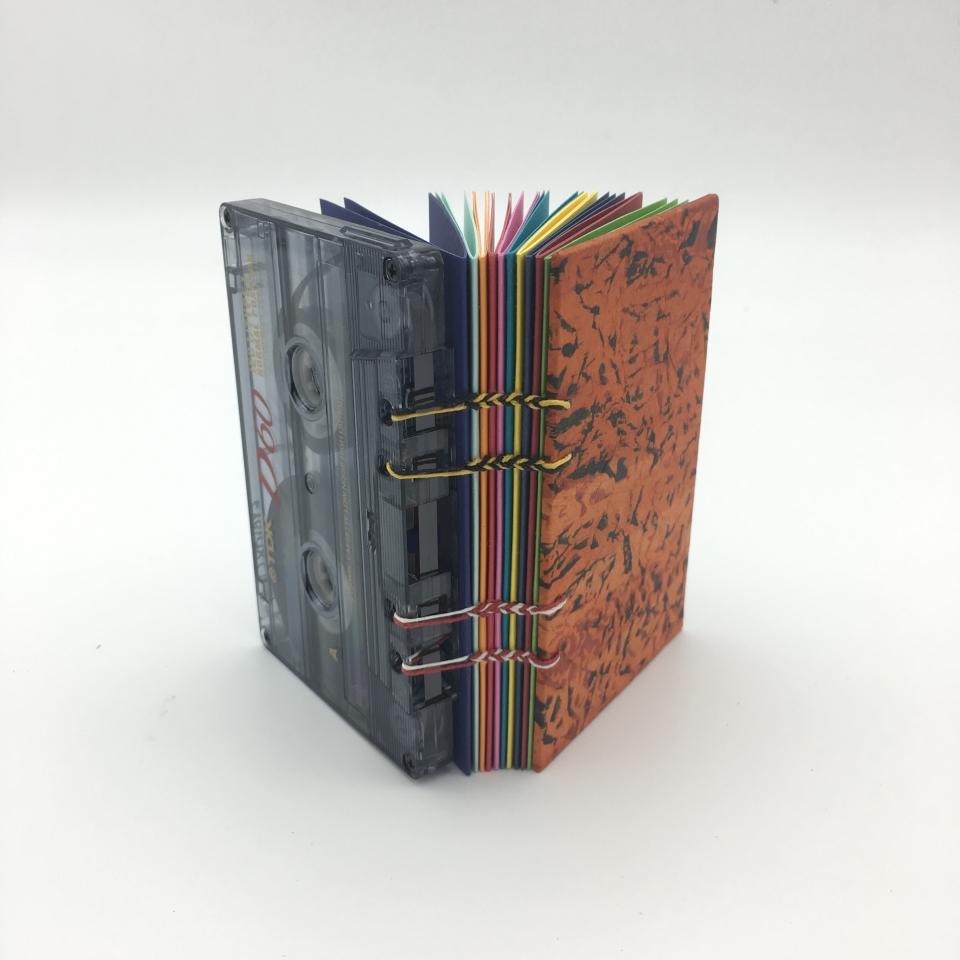

Cassette binding

2017-08-21

My friend Sarah came by to my studio over the weekend to chat and also to work on a cassette binding. Cassettes have four holes which we decided that the Coptic stitch would work well for this as most other bindings require extra holes for the kettle stitches.

Coptic binding is an ancient binding method used by early Christians in Egypt, the Copts, in the second century to the eleventh century. The Coptic binding is the first codex, where a number of folded sheets of paper/vellum/papyrus are bound together by sewing through the folds. As a contemporary format, the Coptic stitch is seen in book arts as a decorative element.

For my cassette binding, I used the cassette for the front cover, signatures of colour paper and a board covered with decorative paper as the back cover. I used black and yellow thread for one set of holes and red and white thread for the other set of holes. We were discussing that with the Coptic it would be ideal to use curved needles for going back to link the previous signatures. Also, when doing the Coptic, I prefer having more signatures as it would better enhance the linking in the stitching.

Coptic binding is an ancient binding method used by early Christians in Egypt, the Copts, in the second century to the eleventh century. The Coptic binding is the first codex, where a number of folded sheets of paper/vellum/papyrus are bound together by sewing through the folds. As a contemporary format, the Coptic stitch is seen in book arts as a decorative element.

For my cassette binding, I used the cassette for the front cover, signatures of colour paper and a board covered with decorative paper as the back cover. I used black and yellow thread for one set of holes and red and white thread for the other set of holes. We were discussing that with the Coptic it would be ideal to use curved needles for going back to link the previous signatures. Also, when doing the Coptic, I prefer having more signatures as it would better enhance the linking in the stitching.

Read More

Doublures

2017-08-07

The definition of a doublure from the Webster dictionary is the lining of a book cover; especially an ornamental lining (as of tooled leather, painted vellum, or rich brocade).

There are many types of doublures, the photo above shows a sunken suede doublure, a contrasting colour edge to edge doublure and also a plaquette showing the process of how to prepare the surface for an edge to edge doublure (from left to right).

A sunken doublure is created by sticking a frame on the board prior to covering. This has to be planned in advance as the shoulder has to accommodate for this thickness. The turn ins are wider to cover the frame and you would cover the forth side of the frame the same way as you would do a leather hinge. The thickness of the material that you use for the frame would be the same thickness as what you would have for the inset.

There are many types of doublures, the photo above shows a sunken suede doublure, a contrasting colour edge to edge doublure and also a plaquette showing the process of how to prepare the surface for an edge to edge doublure (from left to right).

A sunken doublure is created by sticking a frame on the board prior to covering. This has to be planned in advance as the shoulder has to accommodate for this thickness. The turn ins are wider to cover the frame and you would cover the forth side of the frame the same way as you would do a leather hinge. The thickness of the material that you use for the frame would be the same thickness as what you would have for the inset.

Read More

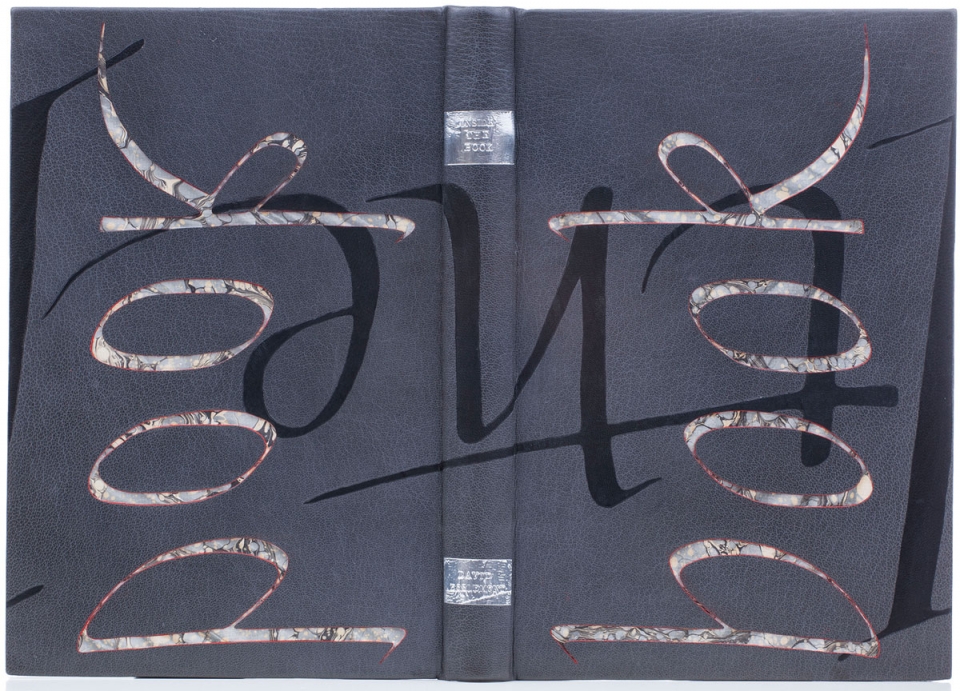

OPEN • SET

2017-03-17

OPEN • SET competition is a new fine binding competition in the United States, that is conducted every three years. The competition is sponsored by the American Academy of Bookbinding, where I've been taking fine binding classes. The competition consists of two categories, an open category where the binder can choose a book of their choice and a set category with a set book. The set book for this year is "Inside the Book" by David Esslemont.

My two books were chosen to go on the traveling exhibit in the United States. Here are the 2017 exhibition venues:

Denver – Denver Public Library – January 5 – 28

San Francisco – San Francisco Center for the Book – February 1 – March 4

Iowa City – University of Iowa – March 8 – April 19

Telluride – Ah Haa School for the Arts – April 24 – May 20

Boston – North Bennett Street School – June 8 – July 14

Austin – Austin Public Library – July 26 – August 26

Seattle – Seattle Public Library – September 8 – October 28

Salt Lake City – University of Utah – November 10 – January 19

My two books were chosen to go on the traveling exhibit in the United States. Here are the 2017 exhibition venues:

Denver – Denver Public Library – January 5 – 28

San Francisco – San Francisco Center for the Book – February 1 – March 4

Iowa City – University of Iowa – March 8 – April 19

Telluride – Ah Haa School for the Arts – April 24 – May 20

Boston – North Bennett Street School – June 8 – July 14

Austin – Austin Public Library – July 26 – August 26

Seattle – Seattle Public Library – September 8 – October 28

Salt Lake City – University of Utah – November 10 – January 19

Read More

Collaborative Book Arts Project

2016-12-15

I've always liked the idea of collaborating with other artists on a project. My ideal project would be to get different artists to contribute to a book much like the Winter Book. This year I got a chance to collaborate with a few Hong Kong artist on a book arts project. This project won the second edition of Open Call for Young Curators organised by Gallery Mur Nomade.

Sojourn with Stranger is a limited edition artists' book curated by Hilda Chan. The project is inspired by Nagasaki (2010), a novel by French writer Eric Faye. Nagasaki is based on a real story about a Japanese man living alone and discovering only after nearly a year that there has been an intruder living in his house. This story addresses the issues of space, ownership, isolation and lack of privacy in modern societies.

I worked alongside Wai Lau (photographer), Beatrix Pang (book designer) and Wawa (poet) to create an edition of 10 books. We printed Lau's photograph on tyvek, cut, scored and folded it into an accordion book. An excerpt of “Anna and Anna”, Wawa's poem, was letterpress printed (in her own hand-writing) onto a cardstock. I then created an origami enclosure to house the different elements. The idea behind the enclosure is that it should be unsuspecting when closed, by opening the enclosure, one reveals the story.

Our project was exhibited at Gallery Mur Nomade from 3rd to 24th of December 2016. In 2017, Tai Kwun collected a copy and exhibited our project at Art Basel, Hong Kong 2017.

Sojourn with Stranger is a limited edition artists' book curated by Hilda Chan. The project is inspired by Nagasaki (2010), a novel by French writer Eric Faye. Nagasaki is based on a real story about a Japanese man living alone and discovering only after nearly a year that there has been an intruder living in his house. This story addresses the issues of space, ownership, isolation and lack of privacy in modern societies.

I worked alongside Wai Lau (photographer), Beatrix Pang (book designer) and Wawa (poet) to create an edition of 10 books. We printed Lau's photograph on tyvek, cut, scored and folded it into an accordion book. An excerpt of “Anna and Anna”, Wawa's poem, was letterpress printed (in her own hand-writing) onto a cardstock. I then created an origami enclosure to house the different elements. The idea behind the enclosure is that it should be unsuspecting when closed, by opening the enclosure, one reveals the story.

Our project was exhibited at Gallery Mur Nomade from 3rd to 24th of December 2016. In 2017, Tai Kwun collected a copy and exhibited our project at Art Basel, Hong Kong 2017.

Read More

There are no matched articles found